QUALITY CONTROL

Procuring orders confirming Quality is the commitment of EUROtex .

Our quality control department is rich with sufficient experienced technical persons and always ensure quality in the production line , finishing and packaging point based on buyer’s instructions. Buyers are always kept in touch with up date regarding production status and shipment. We are happy that we have obtained reputation for sincerity about quality and timely shipment.

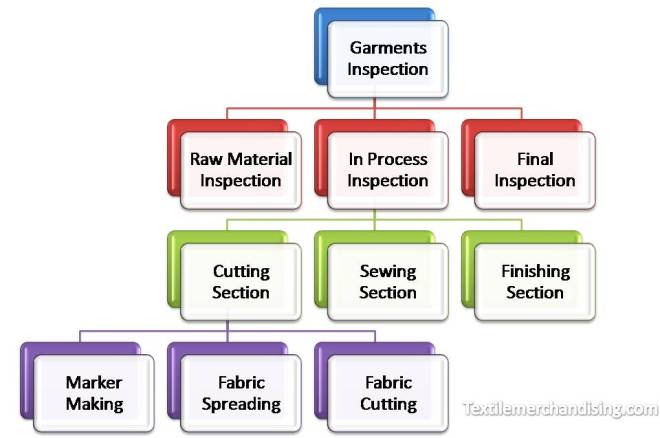

Quality Control : In the apparel industry quality control is practiced right from the initial stage of sourcing raw materials to the stage of final finished garment. Quality control in garment industry is very complex and lengthy task. There are several stages to control quality in garment manufacturing, which are as under :-

- Pre-production quality control

- Quality control during production

- Final inspection

- Quality control to developing a sampling plan

- Post-production quality evaluation

Quality Inspection:

In the apparel industry different types of inspections are to be conducted for improving garments quality. It helps to prevent defects in manufacturing process. Inspection is one of the main tools of quality assurance. During garments productions to ensure quality there are 4 types of inspection process are applied, which are as under :-

- In line inspection

- Table inspection

- Pre-final inspection

- Final or Pre shipment inspection

Beside the above inspections, following defects are to check carefully :-

Sewing defects – Like open seams, wrong stitching techniques used, same color garment, but usage of different color threads on the garment, miss out of stitches in between, creasing of the garment, incorrect thread tension and raw edges are some sewing defects that could occur so should be taken care of.

Color effects- Color defects that could happen are – difference of the color of final produced garment to the sample shown, accessories used are of wrong color combination and mismatching of dye among the pieces.

Sizing defects – Wrong shade of sizes, difference in measurement of a garment part from other, for example- sleeves of ‘XL’ size but body of ‘L’ size. Such defects do not come about has to be seen too.

Garment defects – During manufacturing process defects could happen like – defective zippers, irregular hemming, loose buttons, raw edges, improper button holes, uneven parts, inappropriate trimming, and difference in fabric colors.